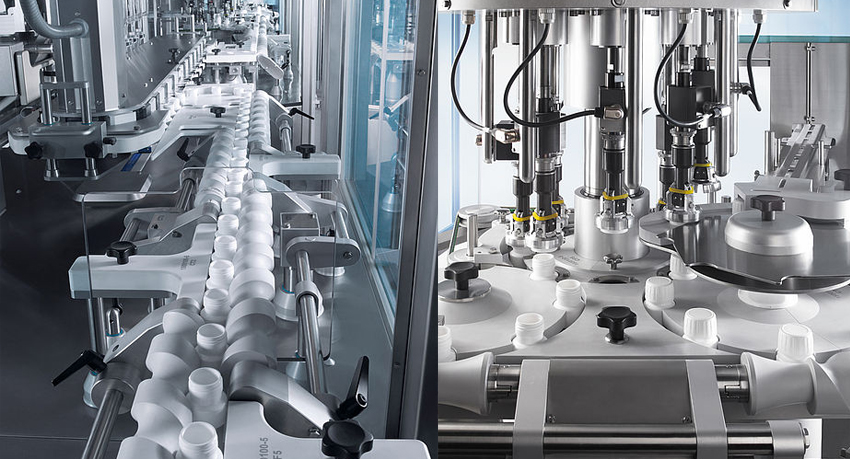

IBC 150的集成整體式結構為藥片瓶裝包裝提供了所有必要的工作站。

該生產線高度自動化,連接最優,集中控制,並且完全靈活。基本型號包括瓶子進料,伺服調節式錠劑計數器,加蓋裝置和瓶子卸料等。

可根據需要集成其他零部件,例如乾燥劑投入機,稱重系統,用於錠劑檢測的相機系統或棉花塞入機。

特點

無限制的瓶子運輸可實現不間斷的產品流——從開始到結束

由於規格零件數量少,規格切換速度快,並且可以自動調整到新的瓶子高度,因此具有很大的靈活性

可擴展的性能:最多四個計數模組和三個加蓋單元可增加計數容量或更高的輸出量,或兩者結合使用,每分鐘最多可裝150瓶或24,000個藥片或膠囊

Cremer紅外計數系統的計數精度達到百分之百

可選的藥片檢查可實現最大的藥物可靠性

用於操作員和產品安全保護的全封閉系統

伺服控制的加蓋系統,用於加工所有類型的蓋帽

SmartControl人機交互介面可以進行集中,直觀的操作

技術規格

最大產量: 150 瓶/分

最大數粒速度: 24,000 粒/分

藥瓶容積:30 - 1,500 cc

藥瓶直徑:25 - 125 mm

藥瓶高度:45 - 200 mm

適用藥瓶材料:HDPE, 玻璃

適用藥瓶形狀:圓形、矩形、橢圓形

適用固體製劑產品:藥片、膠囊

產品長度:3 - 30 mm

產品寬度/直徑:3 - 20 mm

數粒精度:100 %

Bottle line IBC 150

Innovative bottle line for the packaging of tablets and capsules in bottles

The integrated monoblock architecture of the IBC 150 offers all the essential stations for the packaging of tablets in bottles. This line is highly automated, optimally linked, centrally controlled, and completely flexible. The basic model includes stations such as the bottle infeed, servo-regulated tablet counter, capping unit, and bottle discharge. Other elements, like a modular desiccant feeder for canisters or sachets, a weighing system, a camera system for tablet inspection, or a cotton wad feeder, can be integrated as required.

Highlights

Format-free bottle transport for an uninterrupted product flow – from start to finish

Great flexibility on account of the small number of format parts, fast format changeovers, and automated adjustment to a new bottle height

Scalable performance: up to four counting modules and three capping units for added counting capacity or higher output, or a combination of both, for up to 150 bottles or 24,000 tablets or capsules per minute

One hundred percent counting accuracy with the Cremer infrared counting system

Optional tablet inspection for maximum pharmaceutical reliability

Fully enclosed system for operator and product protection

Servo-regulated capping system for the processing of all types of caps

Central, intuitive operation using the HMI SmartControl

Technical Data

Max. output:150 bottles/min.

Max. counting speed:24,000 products/min.

Bottle volume:30 - 1,500 cc

Bottle diameter:25 - 125 mm

Bottle height:45 - 200 mm

Processable bottle materials:HDPE, glass

Processable bottle shapes:round, rectangular, oval

Processable solid dose products:tablets, capsules

Product length:3 - 30 mm

Product width/diameter:3 - 20 mm

Counting accuracy:100 %

特點

快速更換模具

自動進行模具預設定,簡化模具更換

連續性引導式藥瓶傳輸實現高生產力

100%數粒精度

最大程度保護操作員和產品

技術規格

最大產量: 240 瓶/分

最大計數速度:42,000 粒/分

藥瓶容積:30 - 950 cc

藥瓶直徑:35 - 100 mm

藥瓶高度:48 - 193 mm

適用藥瓶材料:HDPE, 玻璃

適用藥瓶形狀:圓形、橢圓形、矩形

適用固體製劑產品:藥片、膠囊

產品長度:2 - 30 mm

產品寬度/直徑:2 - 20 mm

數粒精度:100 %

Bottle line IBC 240

Performance at its best

Pharmaceutically compliant counting, packaging, and labeling: the IBC 240 is an end-to-end system for the non-stop packaging of tablets and capsules in bottles.

Highlights

Fast, tool-free format changeover

Automated format presetting for optimum format changeover without ramp-up and adjustment process

Highly productive with continuous guided motion bottle transport

100-percent counting accuracy with infrared counting system

Operator and product protection as completely enclosed system

Technical Data

Max. output:240 bottles/min.

Max. counting speed:42,000 products/min.

Bottle volume:30 - 950 cc

Bottle diameter:35 - 100 mm

Bottle height:48 - 193 mm

Processable bottle materials:HDPE, glass

Processable bottle shapes:round, rectangular, oval

Processable solid dose products:tablets, capsules

Product length:2 - 30 mm

Product width/diameter:2 - 20 mm

Counting accuracy:100 %