特點

伺服驅動,網路索引,精密傳輸高

生產穩定性,自動調節驅動

可儲存所有模具相關數據以便快速更換模具

小巧,輕便的零組件可快速更換

直觀式操作系統

技術規格

最大產量: 250 板/分

密封原理: 平板式密封

應用範圍: 固體和液體製劑產品

最大模具範圍[index x width]: 130 x 156.5 mm

成型深度: 10/18.5/24 mm

適用成型膜材料: PVC, PVC/PVDC, PVC/Aclar laminations, aluminium forming foil, PP, PET

適用上膜材質: hot sealable materials made of Al, paper, PVC or similar

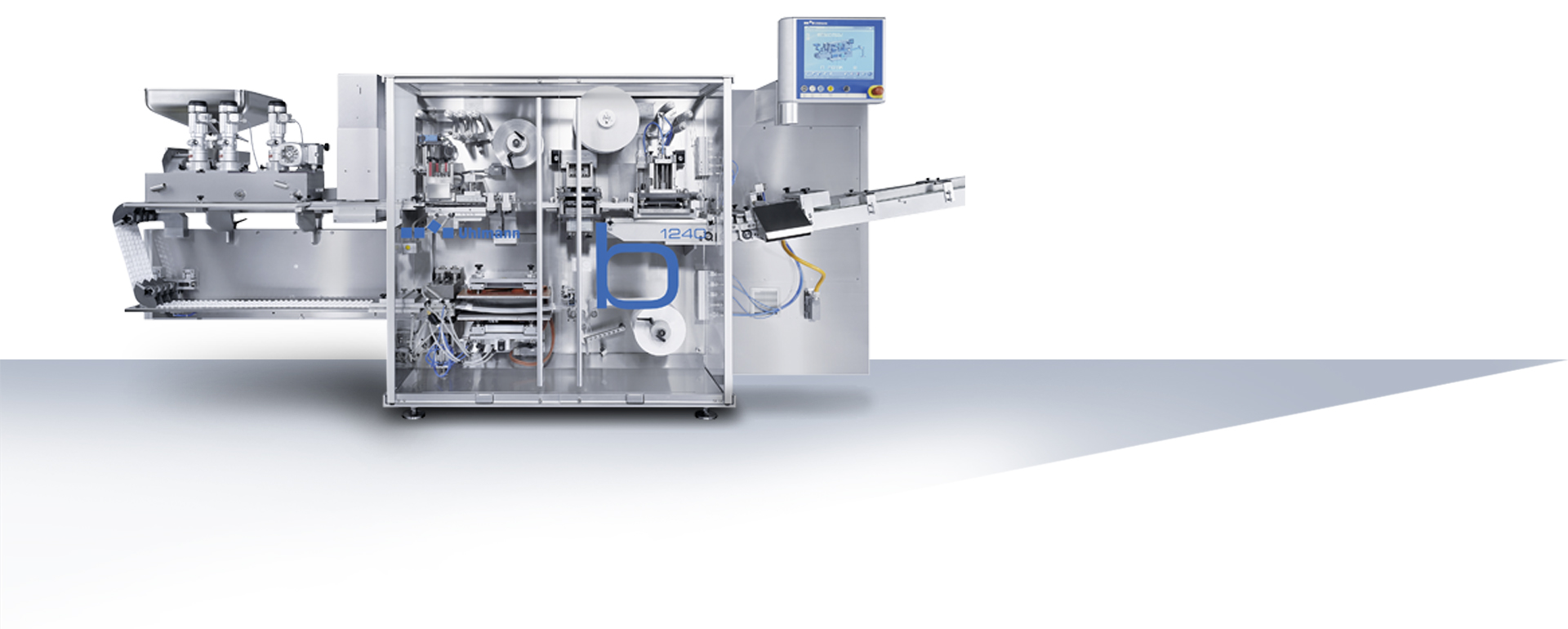

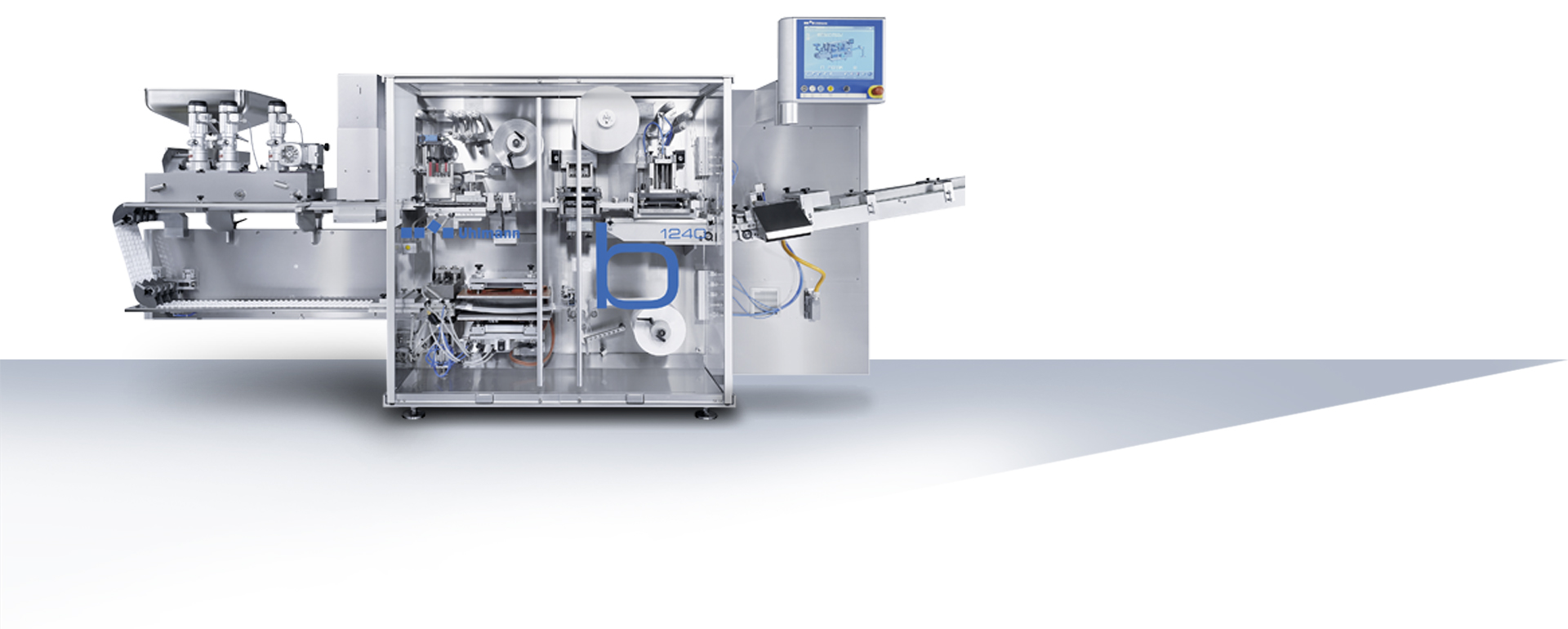

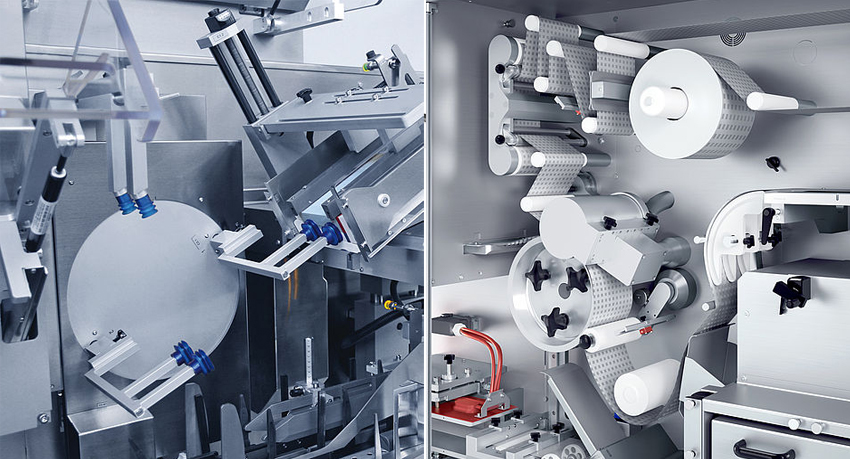

Blister machine B 1240

Versatile and convincing throughout

An established machine concept that meets the technological standards of larger blister machines. For the

flexible, GMP-compliant packaging of solid and liquid dose products at an excellent price-performance ratio.

Highlights

Servo-regulated main drive, web index, and transfer for high-precision operation

Maximum production reliability and top blister quality on account of self-adjusting drives

Storage of all format-related data for quick changeover times

Small, light-weight tools guarantee quick and easy format changeovers

Easy to operate

Technical Data

Max. output: 250 blisters/min.

Sealing principle: platen sealing

Scope of application: solid and liquid dose products

Max. format area [index x width]: 130 x 156.5 mm

Max. forming depth: 10/18.5/24 mm

Processable forming materials: thermoplastics, PVC, PVC/PVDC, PVC/Aclar laminates, Al laminates, PET

Processable lid materials: hot sealable materials made of Al, paper, PVC or similar

Weight: approx. 2,000 kg

特點

溫和:非常小心的操作避免了液體製劑產品的損壞,例如,將送料器中的落差高度降至最低,或壓入和密封站中的集成產的品位置控制。

簡單直觀:使用智慧控制作業系統,直觀地操作泡殼包裝機,並輕鬆進行不同規格的轉換。

靈活:進料器,填充,輸送裝置或自動裝盒 - 可無限選配後端連接系統,滿足所有產品的包裝要求

高效:由產品和泡殼旋轉使模具達到最佳利用率,從而大幅度的減少浪費及將產量提至最高。

技術規格

最大產量: 400板/分

密封原理: 平板式密封

應用範圍: 液體製劑產品

最大模具範圍[index x width]: 195 x 284 mm

成型深度: 42 mm

適用成型膜材料: PET, PET/PE, PET-G, PVC

適用上膜材質: Al, PET, paper

Blister machine BLU 400

Blister machine for the gentle handling of liquid dose products

The BLU 400 handles the pharmaceutical packaging of ampoules, syringes, vials, bottles, cartridges, or pens in blister packs. The compact packaging machine meets all the essential requirements of the pharmaceutical market for the secondary packaging of liquid dose products. As a fully automated packaging system, the BLU 400 offers a convincing performance based on reliable, gentle product handling and flexible, cost-efficient packaging.

Highlights

Gentle: Very careful handling avoids damage to the liquid dose products, e.g., minimum drop heights in the feeder, or integrated product position control in the press-in and sealing station.

Straightforward: Intuitive operation of the blister packaging machine and easy, guided format changeovers with the SmartControl operating system.

Flexible: Whether feeder, fill section, transfer, or cartoner – boundless optional configurations of the packaging system cover all product requirements.

Efficient: Optimum format utilization on account of product and blister rotation, which leads to minimum waste and maximum machine output.

Technical Data

Max. output: 400 blisters/min.

Sealing principle: platen sealing

Scope of application: liquid dose products

Max. format area [index x width]: 195 x 284 mm

Max. forming depth: 42 mm

Processable forming materials: PET, PET/PE, PET-G, PVC

Processable lid materials: Al, PET, paper

由泡殼包裝機、裝盒機組成,形成一個長約8.4米的完整生產線。

BEC 300是適用於所有普通固體製劑產品和各類成型塑模的理想生產線,批量多達7萬包。

其具備了引導性,且無工具即可更換模具,從而確保極短的換線時間——這是所有製藥公司所看重的靈活性包裝生產線。

特點

快速:由於可以在免工具情況下更換少量輕型模具零件,所以可在30分鐘內完成產品換線;光滑的機器表面更可以快速清潔生產線

功能強大:適用於10,000至70,000包的中小批量生產,最大產量為300個泡殼,每分鐘可裝150個 (可選300個)紙盒

簡單直觀:SmartControl作業系統——智慧Uhlmann人機界面,直觀操作和嚮導式產品轉換

量身定制:廣泛用於加工所有常見類型的成形材料,產品形狀,紙箱尺寸和封閉類型; 最大可實現40毫米長的泡殼和100毫米高的紙盒

技術規格

泡殼包裝機

最大產量: 300板/分

密封原理: 滾筒式密封

應用範圍: 固體製劑產品

最大模具範圍[index x width]: 200 x 145 mm

成型深度: 最大12 mm

適用成型膜材料: laminated Al foils, PVC, PVC/PVDC, PVC/Aclar, PP

適用上膜材質: hard Al, soft Al, paper/Al, Al with defined hardness, other on request

裝盒機

最大產量: 150或300盒/分

應用範圍: 泡殼片

最大紙盒尺寸[A x B x H]: 115 x 100 x 150 mm (150盒/分), 105 x 105 x 155 mm (300盒/分)

最多泡殼片數量: 14

最大泡殼片堆疊高度: 95 mm

封口方式: 插耳及點膠

Blister line BEC 300

The added-value machine in the compact range

The packaging line combines a blister machine, cartoner, and feeder, forming an integrated, all-in-one system measuring 8.4 m in length. The BEC 300 is the ideal line for the processing of all common solid dose products and types of forming material in batches of up to 70,000 packs. A guided, tool-free format changeover ensures a short setup time – ideal for all pharmaceutical companies that focus on flexible packaging.

Highlights

Fast: Format changeover in 30 minutes on account of few, lightweight format parts that can be exchanged without tools; smooth surfaces for fast line clearance

Powerful: For small to medium-sized batches of 10,000 to 70,000 packs with a maximum output of 300 blisters and 150 (optionally 300) cartons per minute

Straightforward: Intuitive operation and guided format changeovers with the SmartControl operating system, the smart Uhlmann HMI

Tailored: A wide range of applications for the processing of all common types of forming material, product shapes, carton sizes, and types of closure; blister pockets up to 40 mm long and cartons up to 100 mm in height possible

Technical Data

Blister

Max. output: 300 blisters/min.

Sealing principle: rotary sealing

Scope of application: solid dose products

Max. format area [index x width]: 200 x 145 mm

Max. forming depth: 12 mm

Processable forming materials: laminated Al foils, PVC, PVC/PVDC, PVC/Aclar, PP

Processable lid materials: hard Al, soft Al, paper/Al, Al with defined hardness, others on request

Cartoner

Max. output: 150 or 300 cartons/min.

Scope of application: blister

Max carton size [A x B x H]: 115 x 100 x 150 mm (150 cartons/min.), 105 x 105 x 155 mm (300 cartons/min.)

Max. no. of blister: 14

Max. blister stack height: 95 mm

Types of closure: tuck-in and hot-melt

特點

組合方案靈活,可實現不同規格產品的高效包裝

投資成本低

調試耗時短且工藝轉換快速、無需工具輔助

設計簡潔、占地面積小,帶橢圓形托板輸送軌道

利用最新的控制技術,通過IPC實現

操作嚮導簡便,通過觸控式螢幕顯示

技術規格

最大產量: 14模/分

最大成型深度: 100 mm

成型面積: 200 x 300 mm

封口面積: 250 x 342 mm

Blister KBS-PO

Format and product diversity: hygienically packaged in the smallest of spaces.

The blister machine KBS-PO with oval pallet transport is based on a well-conceived machine concept for the reliable, productive and cost-optimized packaging of small to medium-sized batches. For efficient packaging of different formats.

Highlights

Flexible machine concept for the efficient packaging of different formats

Low capital costs

Tool-free retooling and quick format changeovers

Compact machine design with small footprint and oval pallet transport

State-of-the-art IPC control technology

Intuitive operator guidance via touchscreen

Technical Data

Max. Output: 14 cycles/min.

Blister depth: 100 mm

Sealing area: 200 x 300 mm

Forming area: 250 x 342 mm